Translate:

Aging Wiring

Untangling Issues With Aging Aircraft Wiring

Republished with permission from the October 2017 issue of Avionics News magazine, a monthly publication of the Aircraft Electronics Association.

The FAA and our industry provide several resources for GA owner/operators to educate ourselves about aging aircraft. Wiring is overlooked too often for various reasons. Shops may not be equipped to repair or replace heavy power/starter cables. Owners many times have an out of sight, out of mind mentality. Consider a good inspection of your 40-60 year-old PVC insulated airframe wiring.

ATC reported alternator noise from this Cherokee 140 photos below. Many times RF noise is caused by leaking alternator diodes. An inspection of the power cable also revealed heat damage to the 60 year-old unshielded cable and field wire. With the alternator being overhauled, the owner decided to install shielded cables. I use only polyvinylidene fluoride shield splices due to high abrasion resistance. TECHFLEX fiberglass sleeve with TECHLACE fiberglass tape are affordable solutions to exhaust heat damage.

Old alternator cable laid next to newly installed shielded TEFZEL wires with heat sleeves.

Cessna Voltage Regulator Connector

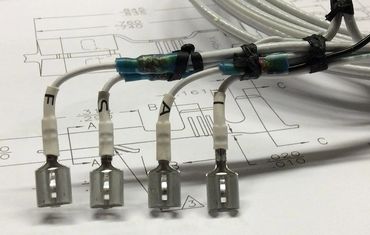

The first time I was called to help a local A&P with wiring involved a voltage regulator problem. The photos below show exactly what I found. The mechanic had already installed a new Plane Power alternator provided by the owner. I was asked to help install a new Plane Power voltage regulator. First problem I noticed was the second from right terminal hanging by two strands. This is the "A" terminal which allows the regulator to sense bus load. Next is "S" which provides power to the regulator with less than half of the original strands. The regulator couldn't sense load requirements even if it was fully powered.

The factory open barrel spade terminal has two separate crimps. The smaller inside barrel crimps the conductor. The larger outside barrel is for insulation support. Note the factory insulation support crimp is not contacting the insulation. Over time vibration at the crimp work hardens and stress cracks individual strands. The new terminals I use are tin plated copper AMP FASTIN like the originals, but with correct insulation support for 18 AWG wire. I also use heat shrink for added strength. A 1/16" hex key makes an excellent removal tool. Sometimes the locking lance is difficult to bend toward the contact. Be careful not to damage the connector removing old terminals.